The convertible glass rear windows of Audi (TT, A3, A4, A5, etc.), VW (Beetle, Golf, etc.), Mini (R 57) BMW (1 Series E88) and various other brands are directly glued to the soft top fabric without a frame. This bonding comes off completely or partially after about 10 years.

Causes are normal environmental influences (e.g. solar radiation, humidity, etc.) and frequent impregnation with solvent-containing impregnators from the spray can. Solvents cause hardening of the adhesives and thus reduce adhesion. The use of the incorrect cleaning agents (containing acids or solvents, etc.) also damages the bonding. A new convertible top costs up to 5,000 EURO / USD including installation and can exceed current value of the vehicle. We have worked intensively on this topic and have developed a do-it-yourself repair solution.

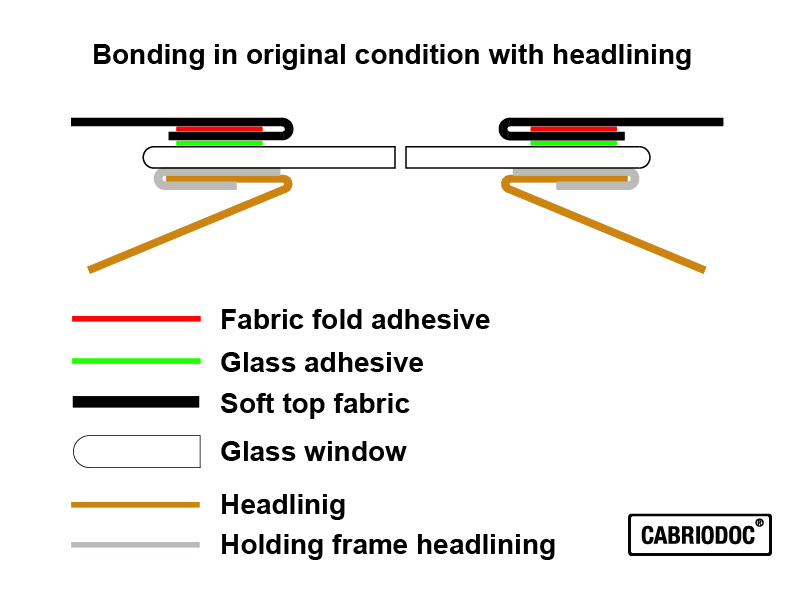

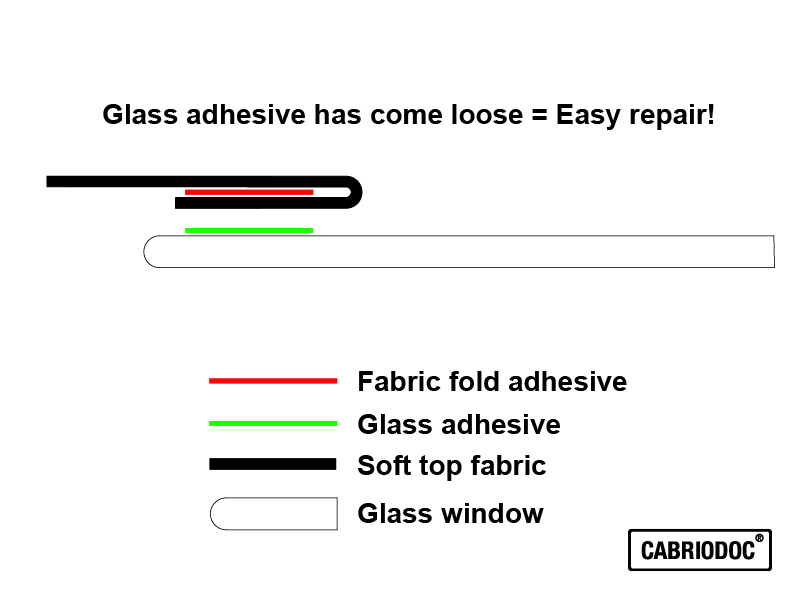

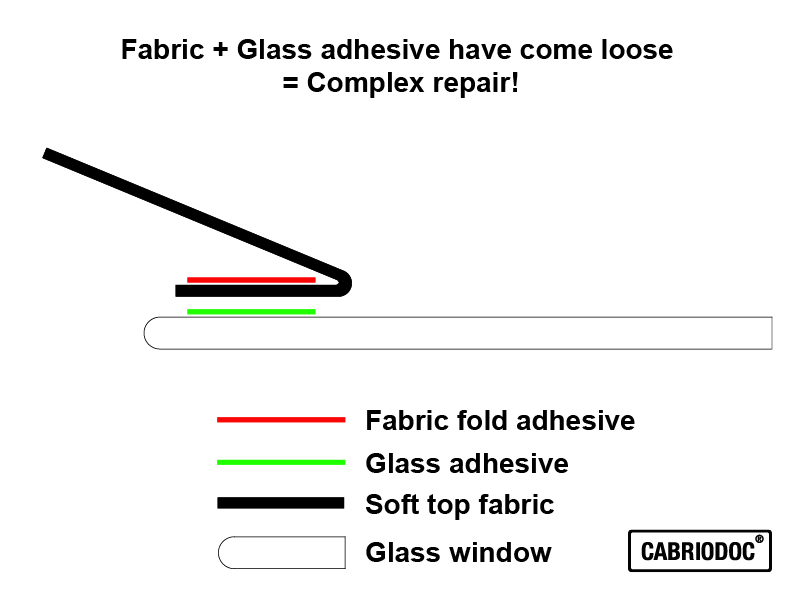

In order to have a clean finish to the convertible top window, the soft top fabric was folded and glued at the factory. If this bonding has also come loose, the glass adhesive will be extremely stressed.Every time the soft top is opened and closed, the soft top fabric is pulled off the glass window almost vertically. Therefore, if you only replace the glass bonding and ignore the fabric fold bonding, you will not achieve a long-lasting repair result. Rebonding the fabric fold is complex. In order to access the fabric fold bonding, the inner headliner (not available on all vehicles!) must be completely or partially removed. In the lower area of the window, the headliner can be removed relatively easily. In the upper area, as well as on the right and left, the headliner must be removed from the frame of the window. This is possible, but requires some experience and craftsmanship. It is easier if the window is completely detached. In this case, the fold is fully accessible and can be fixed and rebonded with foldback clips until fully cured. The window can then be rebonded to the fabric, step by step.

Adhesives - Bonding tests

We have tested almost all commercially available types of adhesive on used original convertible tops. All adhesives have more or less failed. The main problem was the resistance to high temperatures. The soft top and the window can heat up to 80°C to 90°C when exposed to sunlight. Commercially available adhesives are temperature resistant up to 80°C according to the manufacturer. But be careful, these manufacturer's specifications are greatly exaggerated. The "special adhesives" offered on Ebay and Amazon (usually "epoxy resin adhesive" or "two-component structural adhesive") for convertible glass rear windows have also failed here. These "epoxy resin special adhesives" are sold on Ebay and Amazon for 20-30 EURO / USD. Fully comparable 2K epoxy resin adhesives cost 8-10 EURO / USD at the hardware store.

Various epoxy resin adhesives are recommended in the forums. These are offered either in tubes or in syringes without mixing tubes. Without a precision scale, however, it is not possible to mix these adhesives 1:1. If the mixture is not correct, the adhesive cannot adhere well. Also, when mixing manually, air bubbles are automatically added, which is not optimal for curing and function. Epoxy resin adhesives are completely rigid when cured and they cannot absorb stretching and vibration. Epoxy resin adhesives are also fluid and run on sloped repair areas. Conclusion: Epoxy resin adhesives are not suitable!

In the USA, car glass adhesives are very popular. These adhesives are flexible and have very good adhesion properties, but are very difficult to process because they are extremely viscous. A thin application is not possible without loss of adhesion. The repair can only be carried out with thick layers.

So we have tested special industrial adhesives. The CABRIODOC 2K Rapid Adhesive is supplied in professional syringes with a 1:1 automatic mixing tube and is resealable. We were also able to reduce the usual curing time of 24 hours to 12 hours. CABRIODOC 2K Rapid Adhesive is easy to process and does not run. After complete curing, the black adhesive is highly flexible and can withstand temperatures from -30°C to + 90°C. The adhesive can be used for fabric fold bonding (fabric to fabric) and glass bonding (glass to fabric).

WARNING

We strongly advise against repairs with commercial adhesives and silicone. It will not last and a professional repair is no longer possible. The "wrong" adhesives can not be removed completely and the CABRIODOC professional adhesive can no longer adhere. Adhesion to silicone is also completely impossible. If you have already carried out such a repair, we can only give you the following tip: Try the repair again with the same adhesive. Remove the adhesive mechanically where it still adheres, except for a thin residual layer. Where it no longer adheres, remove it completely, either mechanically or with suitable cleaning agents. Then, if available, obtain a suitable adhesion primer from the adhesive manufacturer. Apply this and wait for it to flash off. Then reapply the adhesive and use the CABRIODOC clamping tool to provide the necessary hold until the adhesive has cured.

Bonding with clamping tool

A special tool is required for professional bonding. The soft top fabric must be fixed to the glass window with the necessary pressure until the adhesive has cured. We have developed a special clamping tool with a suction cup for this purpose.

Repair instructions

The repair requires patience and some manual skills. Take your time and proceed exactly according to the instructions. Only in this way the repair can be successful.

You will also need the following additional tools for the repair:

Powder-free disposable gloves, acetone, vacuum cleaner and something to cover the body.

If the glass window has completely detached, foldback clamps are additionaly needed.

First check whether only the gluing on the glass window has come loose or also the fold gluing of the soft top fabric on the back. In this case, the fold gluing must be repaired first. Only after complete curing the glass window can be rebonded.

The ambient temperature must be +10°C to max. +30°C (50°F and 86°F max.). The soft top must be absolutely dry. Do not carry out bonding at high humidity. Do not bond under direct sunlight. Optimum repair environment: Dry garage.

Tip for the cold season: The vehicle heater can be used to heat up the soft top. This means that the repair can also be carried out at low temperatures. Caution: Danger of poisoning from exhaust fumes!

Attention

The adhesive has a application time of approx. 25 minutes. During this time, the parts must be joined together. After 25 minutes, the adhesive will no longer bond. The 25 minute rule also applies to the residual quantity in the mixing tube. If necessary, put on a new mixing tube and dispose of the first 2 cm (0.8 inch). The mixing ratio is not yet correct for the first 2 cm (0.8 inch). The adhesive is therefore unusable here. In case of longer detachments the repair must be done step by step. For this reason, we recommend using a maximum of two sets (2 x 7 pieces) of the clamping devices. The clamping tools should only be removed after approx. 4 hours. The adhesive is partially cured after 4 hours, so it is not yet fully loadable. After 12 hours, the adhesive is fully cured and can be loaded.

Cover vehicle

Cover the working area extensively (e.g. with an old bed sheet). The cover can be tucked under the hood. This prevents scratches and adhesive residue on the vehicle.

Cleaning the glass window

The soft top and the window must be clean and dry. There must be no residue of impregnating agents on the window, otherwise the suction cups of the clamping tool cannot adhere. So test the suction before repairing.

Rebond fabric fold

If necessary, first rebond the fold of the soft top fabric. This also applies to the areas where the windshield bonding is still intact.

Remove the headliner completely or partially.

Lightly saturate cleaning cloth with acetone. Clean the fold and allow to flash off. Do not use household solvents (e.g. nail polish remover, nitro thinner, turpentine, etc.). If necessary, use isopropyl alcohol only as an alternative.

All old adhesives must first be completely removed mechanically and chemically. First dissolve the old adhesive with acetone and then remove it mechanically using abrasives (e.g. coarse sandpaper) or small milling tools (e.g. Dremel multifunction tool with milling or grinding head). Then carry out the final chemical cleaning with acetone. Allow a flash-off time of at least 10 minutes.

Prepare adhesive. Apply adhesive to one side of the fold in a wavy pattern with a height of approx. 1 mm (0.04 inch). After pressing on, the adhesive should cover the entire width of the fold. The adhesive may swell out of the fold by about 2 mm (0.08 inch).

Fix the fold to the window using the clamping tool. Slightly moisten the suction cups of the clamping tool with water and place them with some distance and carefully tighten the clamping screws. After 4 hours, the clamping tools can be removed.

If the window has become loose completely, the clamping tools cannot be used. In this case, the fold can only be fixed and rebonded with generic foldback clips (available as accessory in our store) until it has cured. After this, the window can be rebonded to the fabric, step by step.

Rebond fabric to glass window

Pre-clean the repair area with a vacuum cleaner between the fabric and the window. A lot of dirt has accumulated here over the years.

Cover the window generously with masking tape to protect it from scratches.

Prepare the bonding area. Expand the apparently intact bond by approx. 5 mm (0.2 inch) to the right and left, as the old adhesive no longer adheres completely here.

All old adhesives must first be completely removed mechanically and chemically. First dissolve the old adhesive with acetone and then remove it mechanically using abrasives (e.g. coarse sandpaper) or small milling tools (e.g. Dremel multifunction tool with milling or grinding head). Then carry out the final chemical cleaning with acetone. Allow a flash-off time of at least 10 minutes. The old black primer on the window must also be removed. The black primer is not an adhesion promoter, but only a UV protective layer for the old adhesive. The window can then be additionally roughened with a fine abrasive pad. This is followed by final chemical cleaning with acetone. Allow a flash-off time of at least 10 minutes.The old adhesive must be removed chemically and mechanically as far as possible.

Clean the repair area again with the vacuum cleaner between the fabric and the window. This is the only way to remove residues from the old adhesive and the sanding pad.

Remove masking tape, otherwise the suction cups of the clamping tool will not adhere.

Lightly saturate cleaning cloth with acetone. Carefully clean the repair area with the cleaning cloth between the soft top and the window up to the corners. To make work easier, the cleaning cloth can also be wrapped around a wooden spatula or similar tool. Then allow the cleaning area to flash off for a few minutes. Do not use household solvents (e.g. nail polish remover, nitro thinner, turpentine, etc.). If necessary, use only isopropyl alcohol as an alternative.

Prepare adhesive. Apply adhesive on the window in a wavy pattern with a height of approx. 1 mm (0.04 inch). Do not apply adhesive too thickly, but over the entire surface! The final thickness should be max. 0.5 mm (0.02 inch) after pressing with the clamping tool. If the adhesive is applied too thickly, it may come off the window again after a short time! Work in the adhesive on the right and left at the ends of the new bonding with the brush in order to achieve an optimal transition to the intact old bonding. After pressing on, the adhesive should cover the entire bonding area. This is the only way to achieve a 1 cm (0.4 inch) wide, full-surface bond. The adhesive should swell about 1-2 mm (0.04 to 0.08 inch) onto the window. The cured adhesive can be removed after 12 hours mechanically with the scraper from the window.

Slightly moisten the suction cups of the clamping tool with water and place them with some distance and carefully tighten the clamping screws. Remove after 12 hours.

Carefully remove the excess adhesive after 12 hours with the scraper. First cut the adhesive vertically at the edge of the fabric with the scraper and then scrape off the rest flat. Do not remove the excess adhesive with solvents or other chemicals. A small residual film of the adhesive usually remains on the window. This can be removed very carefully with a little acetone and the cleaning cloth. However, no acetone should get onto the new adhesive.

Finally, here is a list of possible causes for faulty bonding:

1. preparatory work not carried out carefully. Old adhesive not completely removed.

2. adhesive applied too thickly or not over the entire surface. Final thickness after pressing with clamping device max. 0.5 mm.

3. ambient temperature too high or too low during repair.

4. you only bought our adhesive and glued without our clamping tool.

The repair kits are sold exclusively through our webshop

Complete set

CD 2K Rapid Adhesive black 35 g double syringe resealable + 3 x mixing tube.

for approx. 150 cm (59 inch) gluing approx. 1 cm (0.4 inch) wide. Fold bonding (fabric with fabric). Glass bonding (glass with fabric)

Classification of the substance or mixture Regulation (EC) No 1272/2008 (CLP): none. CLP labeling requirement: none

CD Clamping tools (plastic) 6 pieces straight for a rebonding of approx. 50 cm (20 inch) + 1 piece curved for the corners

CD cleaning cloth set with 3 pieces

CD Abrasive fleece approx. 100 x 50 mm ( 4 x 2 inch)

CD masking tape 30 mm x 50 m (1.18 x 1968 inch)

CD Mini scraper

CD Brush

Adhesive set

CD 2K Rapid Adhesive black 35 g double syringe resealable + 3 x mixing tube resealable

for for approx. 150 cm (59 inch) gluing approx. 1 cm (0.4 inch) wide. Fold bonding (fabric with fabric). Glass bonding (glass with fabric)

Classification of the substance or mixture Regulation (EC) No 1272/2008 (CLP): none. CLP labeling requirement: none.

Clamping device set

CD Clamping tools (plastic) 6 pieces straight for a rebonding of approx. 50 cm (20 inch) + 1 piece curved for the corners

Mixing tube set

CD mixing tube set with 3 pieces

For all sets NOT included:

Powder-free disposable gloves, acetone (alternatively isopropyl alcohol), vacuum cleaner and something to cover the car body (e.g. an old bed sheet).